paramelt products

High performance anti-ozone waxes for reliable protection.

The Okerin brand, originally established by Astor in the UK and further developed by Paramelt, has found extensive global application amongst all of the major international tire manufacturers.

In technical applications such as belts, hoses, gaskets and mats and shoes soles Akcera™ and Protektor™ brands have been established to meet the specific demands of these technical products.

Okerin™ Akcera™ and Protektor™ anti-ozone waxes have been carefully formulated with a selected blend of highly efficient mineral and synthetic waxes to provide optimal protection in a range of application scenarios.

Paramelt produces anti-ozone waxes in Europe (the Netherlands) and Asia (China), allowing global manufacturers with diverse regional sites the possibility of sourcing anti-ozone wax with equivalent profiles from the most advantageous location to ensure continuity of supply and optimized operational logistics.

paramelt products

High performance anti-ozone waxes for reliable protection.

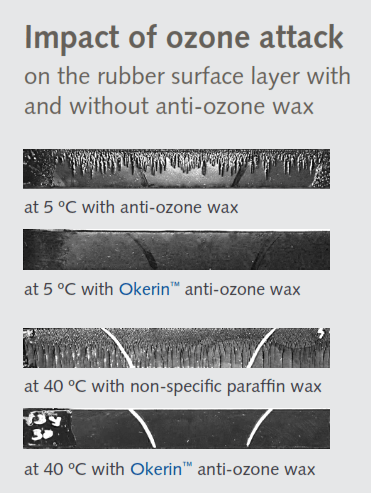

Atmospheric ozone attacks the double bonds of unprotected rubber rapidly, forming an unstable structure known as molozonide. This is the first destructive step because a chain has been broken. This localized surface attack makes ozone degradation visible as surface cracks perpendicular to the direction of stress.

When articles are exposed to tensile strain greater than a threshold value during exposure, cracks grow continuously at a constant rate. The rate of ozone degradation is proportional to the ozone concentration and accelerated by rise in temperature.

Incorporated during rubber compounding, blended waxes, carefully formulated with paraffin and microcrystalline waxes of the right molecular weight distribution, will migrate to the surface of the rubber article after vulcanization to form a thin protective film which acts as a barrier for optimum ozone protection.

This protective film of anti-ozone wax:

For any given wax in a specific rubber compound, there is a marked dependence on migration rate and generally, a peak migration temperature is found. As a result both temperature and rubber formulation are critical factors affecting wax performance. Therefore, to achieve long-term protection across a given temperature window, it is necessary to build a suitable blend of waxes to provide the required migration at different time and temperature intervals.

It is therefore critical to define the expected operating temperature environment as well as the time scale over which protection is required in order to accurately formulate the required wax package.

Paramelt offers a comprehensive range of Okerin anti-ozone waxes, formulated to provide optimal performance at different operating temperature ranges in a number of different rubber systems. These products are used by a vast majority of global tire manufacturers and are known for their consistent quality and performance.

The standard products cover a number of typical operating environments, such as:

These products are able to cover the majority of typical tire applications encountered but we have the knowledge required to develop bespoke products for your specific requirements should this be needed.

Atmospheric ozone is able to attack the double-bonds of unprotected rubber compounds by a free-radical mechanism. This reaction occurs quite rapidly and quickly leads to surface breakdown visible as cracks in the structure of the material. One way to protect rubber articles such as tires from perishing in this manner, is to introduce a migratory barrier material into the rubber compound which exudes to the surface of the rubber and forms a protective layer against free-radical degradation. One of the most common additive solutions is the use of hydrocarbon waxes of varying chain length and morphology to provide protection across a range of temperature and time scale requirements.

Protective compounding of rubber involving physical protection of the surface using a wax film is by no means a new concept, with the first patent claiming such protection dating back to 1881. Over the intervening years a lot has been learned about the key factors influencing compatibility and migration rates as well as the development of new wax types and fractions.

Paramelt

Dutch, since 1898

revenue 2023: €263 mln

# employees 2023: 502

owned by Ter Group

Ter Group

German, since 1908

revenue 2023: €910 mln

# employees 2023: 1140

owned by Westphal family

# active formulas

~100 rubber waxes

Annual re-investment rate

~10%

# laboratory requests

> 1000 last year

# new commercial products

~110 last year

Top 3 reasons to

recommend Paramelt*)

– reliable supplier

– consistent quality

– value for money

*) Customers survey Europe and USA

Financial stability

D&B rating 1

Certifications

IATF 16949:2009

ISO 9001:2015

manufacturing sites

Europe : 3

USA : 3

China : 2

tire & rubber customers

in 27 countries

Average employee retention

> 12 years

Paramelt = ‘knowledge & experience’

recognized by > 85% customers

(Customers survey Europe and USA)

With 8 production facilities delivering in more than 80 countries, we have truly global perspective and local service.