Paramelt is uniquely positioned as a truly global, independent wax specialist. We are able to source, modify and combine mineral waxes from all over the world to consistently deliver exactly the wax you require.

Waxes

With our global supply network and extensive product range, we have extremely detailed knowledge of all major classes of wax. We can select and supply the appropriate wax for your application from our broad portfolio of mineral, vegetable and natural waxes.

Paramelt’s primary specialism lies in mineral hydrocarbon waxes such as microcrystalline waxes, intermediate and paraffin waxes & Fischer-Tropsch (FT) waxes.

In addition to providing fully tailored wax solutions, we also work with a number of partners where our unique experience, material portfolio and process capability offers a value added contribution to their business through bespoke developments or tolling.

Rely on usMicrocrystalline waxes

Within the group of mineral waxes, microcrystalline grades provide the greatest diversity in thermal and physical characteristics and are used in a very broad range of applications, such as cosmetics, chewing gum, cheese waxes and adhesives.

Paraffin & intermediate waxes

Paraffin & intermediate waxes tends to be more regular in structure with more clearly defined properties, although there can be critical performance differences depending on their source and means of production.

Fischer-Tropsch waxes

The Fischer-Tropsch process enables the production of synthetic paraffin & microcrystalline waxes. Through careful selection, modification & fractionation, we are able to offer grades with unique characteristics compared with commonly available materials.

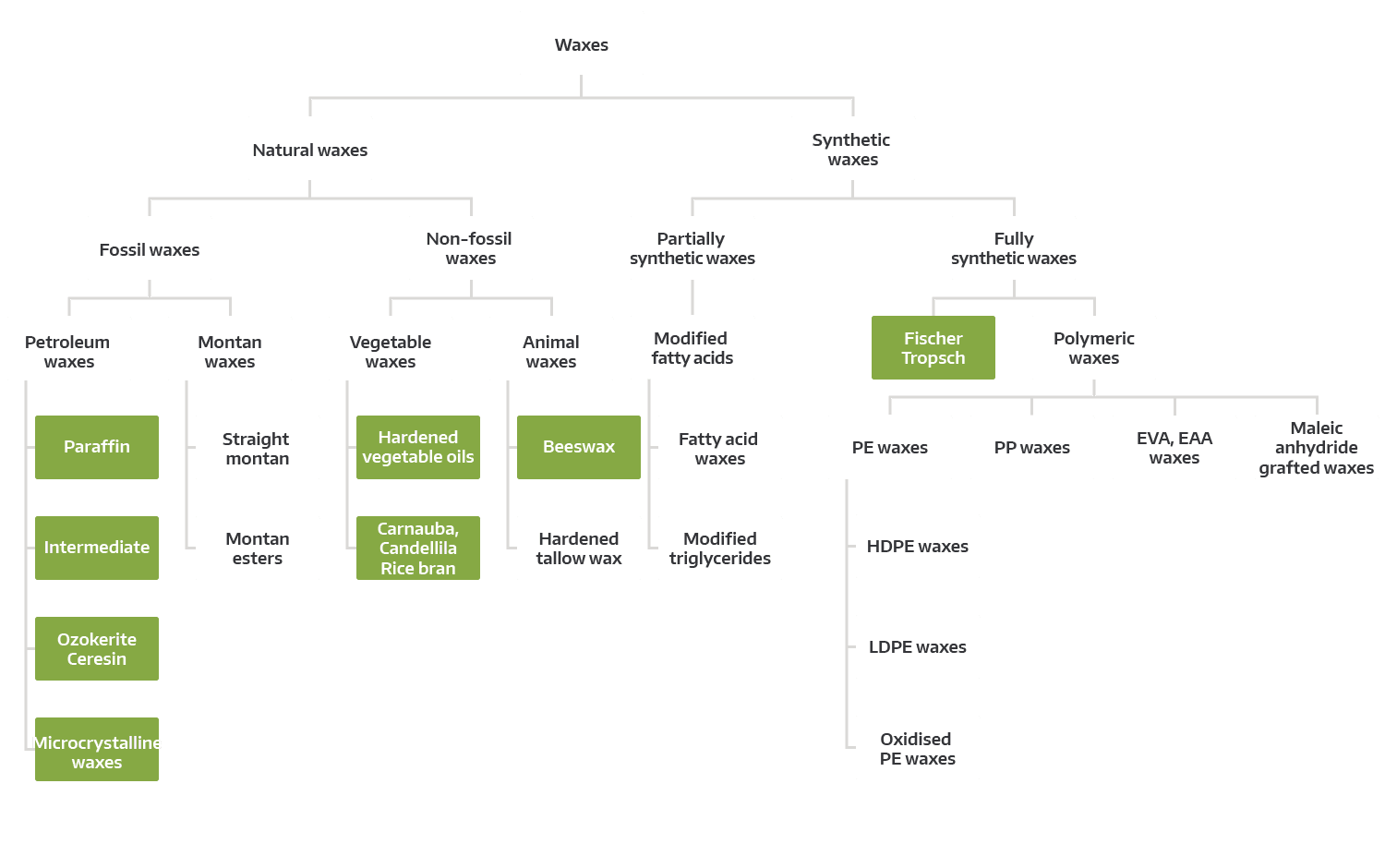

Wax classification

The world of wax includes an extremely broad range of wax materials with different physical and chemical characteristics either of natural or synthetic origin. We are working with all key types of wax and can help you select the appropriate wax for your application.

Our primary specialism lies in the fields of mineral hydrocarbon waxes, both petroleum based waxes such as microcrystalline, paraffin and intermediate waxes, as well as the synthetically produced Fischer-Tropsch waxes.

In addition to the mineral waxes, we work extensively with naturally sourced materials such as vegetable waxes, carnauba wax and beeswax, especially in fields such as cosmetics & personal care, cheese waxes and flexible packaging grades.

We produce in ![]() food safe facilities

food safe facilities

key waxes we offer

We can select and supply the appropriate wax

for your application from our broad range:

Long chain paraffinic molecules can also be synthesized through the Fischer-Tropsch gas-to-liquid (GTL) process, resulting in relatively high melting and hard waxes. Originally developed in Germany as an alternative route to produce automotive fuel from gasified coal, for a long time the process was only practiced in commercial volumes in South Africa and Malaysia. Over recent years there has been a significant growth in production of synthetic fuels and installation of major new GTL fuel plants in the Middle East and China.

Along with the fuel, high molecular weight waxes are produced in the process and need to be removed before sale. In their crude state these FT waxes can vary dramatically in terms of stereoregularity and molecular weight distribution. The crude waxes are typically fractionated into tighter cuts to offer a number of standard melting point grades.

Although products can have a comparable melting point, the detailed distribution of the wax can vary dramatically based on both the source material and the fractionations process. Paramelt knows all the available feedstocks and have established their key features and differences. We are able to select, formulate and further refine these waxes to achieve specific characteristics and application properties, thereby creating novel and unique grades of FT wax.

Through our global sourcing position and significant capacity investments, Paramelt has established the necessary infrastructure to bring these exciting new wax types to market.

As the name suggests the description is a ‘catch all’ categorization to use to encompass all mineral wax fractions, which fall outside the recognized description of a paraffin or a microcrystalline wax. As a result of this loose definition, this category of waxes can vary tremendously in terms of melt point, viscosity and crystallinity balance.

Paramelt has access to a diverse range of such products and also knows how to put together an equivalent balance of properties via numerous alternative formulating routes.

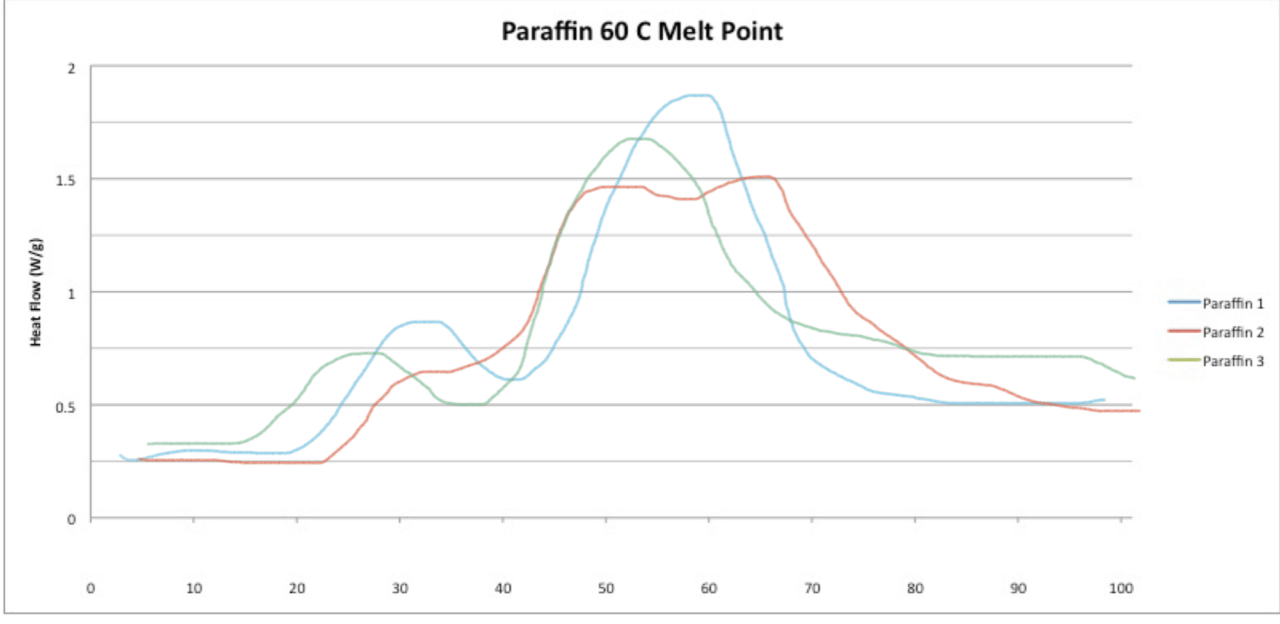

Paraffin waxes are distinguished by their highly linear structure and contain a proportionately lower content of irregularities in the molecular chain. As a result, the paraffin waxes crystallize rapidly and easily form large macro-scale crystals which can be up to millimeters in size. Consequently, pure normal paraffins tend to be hard, brittle materials, which can lead to characteristics such as high gloss, excellent moisture barrier and fast congealing.

Refineries fractionate the waxes using different processes and operating conditions in order to separate different cuts of material from the overall paraffin distribution in the base feedstock. Usually paraffin wax cuts are sold according to the measured congealing points of the fraction. However, depending on the process, operating conditions and feedstock used the resulting products will possess dramatically different molecular characteristics.

Depending on the origin of the base crude, there will be a different overall distribution in carbon chain length which will define the relative ratios of the paraffin fractions which are available.

Therefore, in many cases different streams will be blended together in order for the refinery to consistently achieve the target specification or to provide additional quantities of a fraction, which may be ‘short’ in the available feedstock. This can have a substantial impact on critical physical characteristics.

Our core competence is a comprehensive understanding of the key characteristics of paraffin wax, depending on the supplier and feedstock base and how these aspects link through to critical application properties.

Building on this knowledge, we understand how to ‘assemble’ the right characteristics in the paraffin wax independent of where the wax is coming from, which allows us to ensure long-term quality, security and consistency of supply.

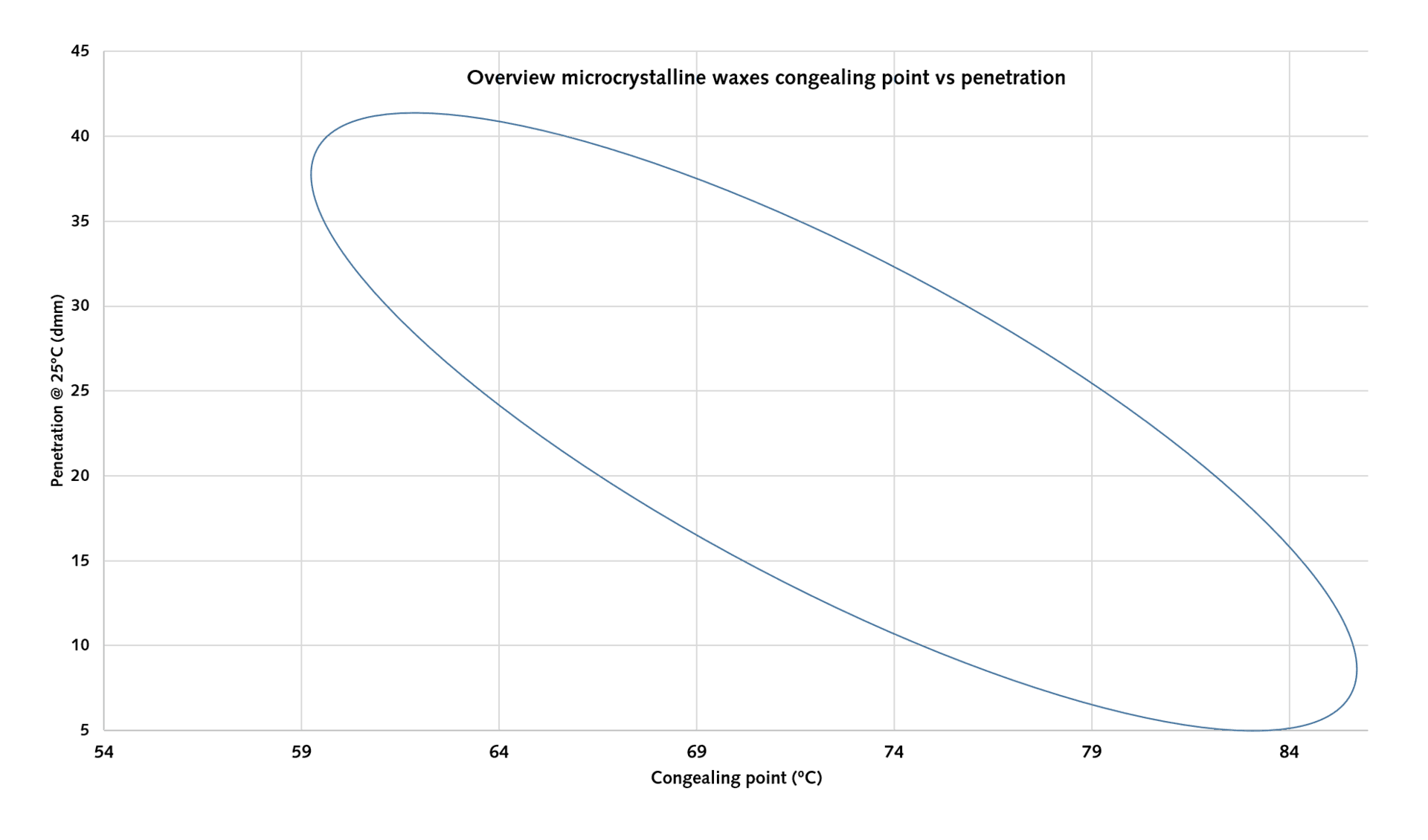

Microcrystalline waxes are higher molecular weight mineral hydrocarbons and tend to be at the upper end of the typical melting point range. Depending on the source and processing of the wax significant differences in chain morphology are apparent providing waxes that can vary from hard high melting (up to 90⁰C) materials to softer and more flexible types with melting points as low as 65⁰C.

In addition to a longer chain length than paraffin waxes, the microcrystalline waxes tend to contain more irregularities in the molecular structure. These irregularities have a significant impact on the ability of the wax to crystallize which in turn influences the crystal size (from which the name ‘microcrystalline’ is derived) as well as the overall degree of crystallinity. The final flexibility of the product is strongly influenced by this morphology, which provides for a great diversity of material characteristics to meet the needs of very many different applications.

Our primary specialism lies in the fields of mineral hydrocarbon waxes, both petroleum based waxes such as microcrystalline, paraffin and intermediate waxes as well as the synthetically produced Fischer-Tropsch waxes. In addition to the mineral waxes we work extensively with naturally sourced materials such as vegetable waxes, carnauba wax and beeswax, especially in fields such as cosmetics & personal care, cheese waxes and flexible packaging grades.

Paramelt has an extensive and in-depth understanding of molecular characteristics vs wax performance requirements. We are able to source a comprehensive range of microwaxes as well as tailoring blends to deliver the targeted requirements for most applications, including chewing gum, cosmetics & personal care and adhesives, and can work with you to develop the optimum material for your needs.

We produce under highly controlled GMP conditions certified to FSSC 22000 standard.

Some of our key standard microcrystalline waxes are:

| Product | Drop melting pt (⁰C) | Congealing pt (⁰C) | Pen @ 25 ⁰C (dmm) | Visco @ 100⁰C (mPa.s) | Colour ASTM/visual |

|---|---|---|---|---|---|

| Paramelt HMP | typical 89 | 82 - 86 | 8 - 18 | 11 - 16 | typical Offwhite |

| Microwax ZG | 78 - 86 | 73 -79 | 22-32 | 10 - 16 | 0.0-0.4 |

| Microwax 13359 | 76-84 | 70-76 | 20 - 30 | 11 - 16 | 0.0-2.0 |

| Paramelt LMP | typical 68 | 62 - 66 | 20 - 35 | 11 - 16 | typical Yellowish |

This short listing is intended to provide an illustration of our extensive range of grades.

Toll manufacturing, viable & reliable

Do you intend to focus on your core business and outsource part of your production? On a daily basis Paramelt has proven to many well known partners that contract manufacturing is a viable and reliable alternative. Want to know more about our approach and our capabilities in processing thermoplastic products?

our dna

Paramelt

Dutch, since 1898

revenue 2023: €263 mln

# employees 2023: 502

owned by Ter Group

Ter Group

German, since 1908

revenue 2023: €910 mln

# employees 2023: 1140

owned by Westphal family

Top 3 reasons to

recommend Paramelt*)

– reliable supplier

– consistent quality

– value for money

*) Customers survey Europe and USA

# active formulas

~2750

Annual re-investment rate

~10%

# laboratory requests

> 1000 last year

# new commercial products

~ 110 last year

Financial stability

D&B rating 1

manufacturing sites

Europe : 3

USA : 3

China : 2

customers in

87 countries

Average employee retention

> 12 years

Paramelt = ‘knowledge & experience’

recognized by > 85% customers

(Customers survey Europe and USA)

Let's connect

With 8 production facilities delivering in more than 80 countries, we have truly global perspective and local service.